Written By Richard Holdener

Photography by the Author

What’s not to love about the Gen-3 Hemi? Sure, the LS family gets the lion’s share of the attention, but a case can be made that the Hemi is every bit as good. After all, it shares a number of traits, including impressive cylinder head flow that all but dictates any Hemi performance combination starts off with a leg up over the competition.

Perhaps the biggest thing the Hemi has going for it is the legendary name. Mention the phrase LS and many people, especially performance enthusiasts, will recognize the name. By contrast, toss out the word Hemi and (thanks to Mopar’s amazing marketing team over the last five or six decades) and everyone (even non-car people) knows what you mean. In the automotive world, the term Hemi is far and away the most recognizable performance designation in the industry. Historically speaking, the previous Hemis were certainly a racing success. Thanks to development and technology, the modern Hemi faithfully continued the legacy, though Dodge is said to be considering dropping the magical V-8 in favor of 6-cylinder (likely boosted) performance. Are we seeing the swan song of the legend? Lucky for enthusiasts, there are plenty of Gen 3 Hemis just waiting for upgrades in the local junkyards.

Dodge saw to it that stock Gen-3 Hemis were plenty powerful, even those destined for mundane (workhorse) Ram applications. As good as the various Hemis might be (5.7L, 6.1l, 6.4L and Hellcat/Demon variants), one of the great things about the Hemi is the way they respond to performance upgrades. After all, we all want our personal touch on our Hemi, and who among us doesn’t want their Hemi to be just a little (a lot) faster? What happens when you pull up to the light next to a supercharged Shelby or ZL-1 Camaro in your NA Hemi-powered Ram, Challenger or Charger? A Hemi is good, but bringing a naturally aspirated knife to a boosted gunfight will likely have predictable results.

Lots of Hemi owners opt for the usual performance mods (think ported heads, cam and/or intake), but what a Hemi owner, especially an early 5.7L owner, really needs is boost! Just how receptive are the Gen-3 Hemis to boost you ask? To answer this question, we decided to take TorqStorm up on its offer to test one of the company's (many) centrifugal supercharger kits. Because we wanted to run this test on the engine dyno, we installed the kit (designed for a late-model Hemi vehicle) on a 5.7L crate motor supplied by Mopar Performance. Shout out to Steve Dulcich for the loan of his 5.7L Hemi crate motor.

Much milder in as-delivered trim, the early 5.7L Hemi test motor had been previously subjected to a number of performance modifications. Years ago, the Hemi had been treated to a host of mods that included a healthy hydraulic-roller cam profile and a set of ported stock heads (from Total Engine Airflow). Factory Hemi motors relied on some type of long-runner, EFI manifold (truck, SRT8 and Magnum), but this crate motor came with a short-runner, single-plane intake. The Mopar Performance intake offered the unique ability to be run in fuel-injected or carbureted guise. For our testing, we chose to run it with the port injection supplied with the crate motor using a 4150, 4-hole throttle body.

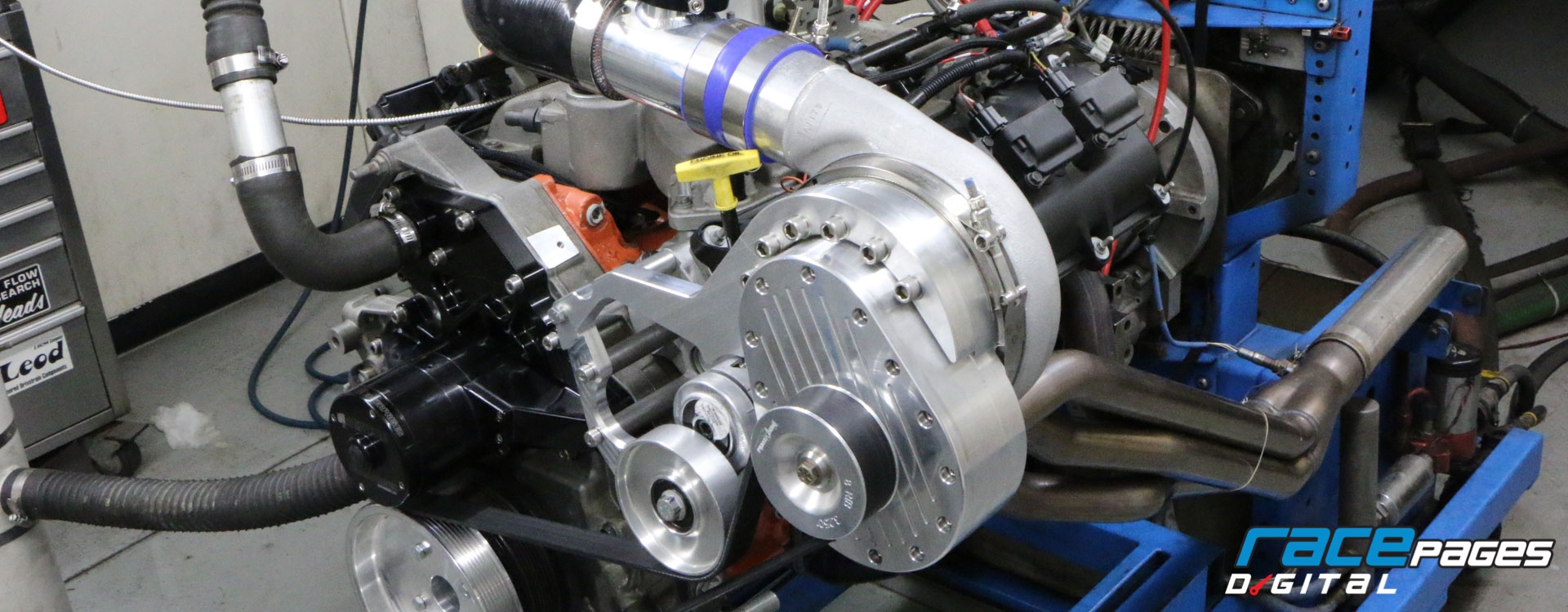

Though the TorqStorm blower kit was originally designed to blow through a long-runner, EFI intake, we simply attached the outlet of the blower to a simple (blow-through) carb bonnet to work on the 4150 throttle body. The highlight of the kit was the TorqStorm supercharger head unit, capable of supporting over 700 hp (we have run them on other applications at well over 700 hp). The kit included the necessary mounting brackets, tensioner and crank pulley assembly (with pin kit).

To illustrate what the TorqStorm blower had to offer the Hemi combination, we started our testing by running the Hemi in normally aspirated trim. Without a baseline, we would have no idea how much power was added by the blower. In prep for the test, the modified Hemi was equipped on the dyno with a Meziere electric water pump, 1 7/8-inch, Hooker long-tube headers and a Holley HP management system. After tuning the naturally aspirated trim, the modified 5.7L produced peaks of 515 hp at 6,900 rpm and 423 lb-ft of torque at 5,900 rpm. After hooking up the the TorqStorm supercharger with the 3.25-inch blower and 8.0-inhc crank pulleys, we were rewarded with a peak boost pressure of 10 psi.

The blower combo was run with a mixture of 91 and 100-octane fuel, dialed in using the Holley HP management system. After tuning, the supercharged Hemi produced 677 hp and 585 lb-ft of torque. This represented gains of 162 hp and (oddly enough) and matching 162 lb-ft of torque . Having exceeded 700 hp with this same blower on another (LS) application, we know there was more power to be had. But even at 675 hp, imagine what that would be like in your favorite (especially early) Dart, Charger or Challenger.

The only thing better than a Hemi... is a boosted Hemi.

A better choice might be any of the long-runner, factory intakes (Magnum, SRT8 or even Ram truck), but this Mopar Hemi crate motor featured a short-runner, single-plane MP manifold.

The MP single-plane intake featured individual port fuel injection. To supply the necessary airflow, it was also equipped with a 4-hole, 4150 throttle body.

Given the calculated power output of the 5.7L Hemi under boost, we chose a set of 60-pound fuel injectors. The dyno fuel system also featured a boost-referenced regulator and Aeromotive brushless fuel pump to ensure adequate fuel supply to the supercharged Hemi.

Since the boosted air supplied to the motor must also find its way out, we equipped the supercharged Hemi with a set of Hooker 1 7/8-inch, long-tube headers (for a Magnum application)

With tuning critical for a supercharged Hemi, we made sure to dial in the air/fuel and timing using a Holley HP Management system.

To establish the gains offered by the TorqStorm blower, we first ran the Hemi naturally aspirated. Run with the cam, single-plane intake and 4150 throttle body, the modified 5.7L Hemi produced 515 hp at 6,900 rpm and 423 lb-ft of torque at 5,900 rpm.

The press-fit, factory dampers can actually slip on the crank when subjected to the added load of driving the blower, so we took steps to eliminate this possibility by pinning the factory crank (and supplied hub).

TorqStorm supplied this drill index and kit to facilitate pinning the crank. Having the right tools made this process simple.

With the pinned hub bolted in place, we installed the larger, 8.0-inch, 8-rib crank pulley. The larger pulley offered increased blower speed for additional flow and boost.

With the crank and pulley ready, we began the blower installation by securing the mounting bracket for the blower. Installation of the blower was simple and straight forward.

The kit from TorqStorm was designed to run factory power steering. Unfortunately, our crate motor lacked the power steering pump necessary for installation. To cure the problem, we whipped up these steel spacers to properly locate the blower mount to the cylinder head.

Once the mount had been installed with our makeshift power steering spacers, we were free to install the supercharger, spring-loaded tensioner and blower belt. Fear not, we installed the remainder of the blower mounting bolts prior to running.

Supplied by TorqStorm, the kit featured a 3.25-inch blower pulley. This was combined with an 8.0-inch crank pulley to produce a peak boost of 10.0 psi on our Hemi.

We know from previous testing with this blower that the TorqStorm head unit will support over 700 hp.

This carb hat was originally designed for a carbureted application, but worked perfectly on our 4150 throttle body.

One of the key elements of the kit was this blow-off valve. The valve was designed to ensure longevity of the blower by eliminating unwanted pressure spikes that can occur under high-rpm, lift-throttle conditions.

After dialing in the tune on the TorqStorm-supercharged Hemi, we were rewarded with peak numbers of 677 hp at 6,500 rpm and 585 lb-ft of torque at 5,500 rpm (at 10.0 psi).

Graph-Modified 5.7L Hemi Crate motor-NA vs TorqStorm (10 psi))

Any time you add an extra 160+ hp, you are going to feel it. The dyno test revealed that the modified 5.7L Hemi responded very well to boost (honestly, what motor doesn’t?). After boost, the power output of the 5.7L increased from 515 hp and 423 lb-ft of torque to 677 hp and 585 lb- ft of torque. The blower has more power to give at higher boost levels, but at this point an intercooler might also be a good idea.

Sources

ARP

(800) 826-3045

Arp-bolts.com

Holley/Hooker/NOS

270 782-2900

www.holley.com

Mopar

www.Mopar.com

MSD

(915) 855-7123

www.msdperformance.com

TorqStorm Superchargers

(616)-706-5580

Torqstorm.com

Westech

(951) 685-4767

www.westechperformance.com