Written by Jason Reiss

Photos by Visner Engine Development from the FSC files

In the world of high-stakes doorslammer drag racing, power is king. In classes like Radial vs. The World and Pro 275, the winning combinations have traditionally been based around the Hemi engine and the 481-X, both of which have been honed by several manufacturers and engine builders over the years into nearly unbeatable combinations, with parts readily available for repairs.

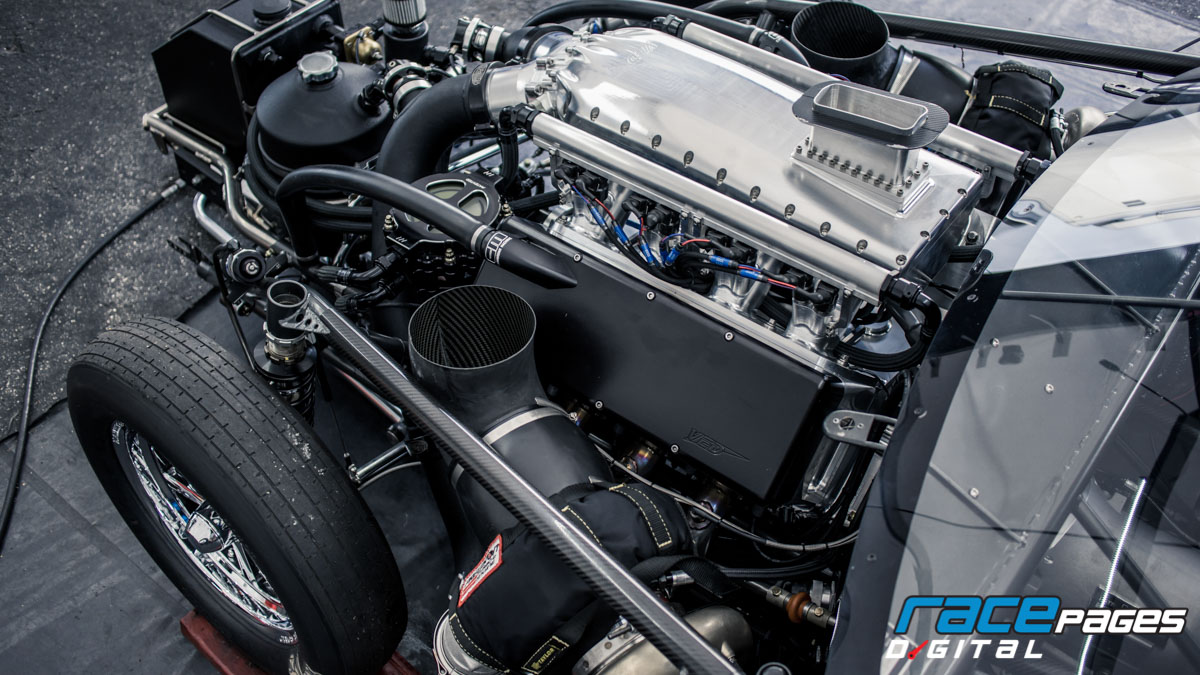

However, there's a new player on the block developed by an established winner with roots that extend throughout nearly all forms of competitive motorsports. David Visner of Visner Engine Development crafted this all-new, 4.600-inch-bore-space, small-block Chevrolet-based engine platform into one that has already established itself as a player in these dominant forms of drag racing.

A version of the engine is also under the hood of Nick Agostino's Pro 275 car, which had success earlier this year, winning the Pro 275 class at the US Street Nationals. We caught a glimpse of it under the hood of Mark Woodruff's new Radial vs. The World Camaro at Lights Out 11. We pursued Visner and Woodruff's engine builder, Kris Nelson, of Nelson Competition, to uncover the details of this beautiful, billet bullet.

Mark wanted to do something different. He has three of the Hemis that I built for him for the Corvette, and he knew it was time for a new car, Nelson explained. We started really analyzing the rules, and his first thought was to do a small-block with a screw. It's having some success, but it wasn't really our thing. So then we got to talking and decided to collaborate on a combination that could help my business and do something different.

We thought the small-block would be a good option, and I started doing some research to see how it fit into the rules. We talked to Dave and stressed to him that we'd need to be able to duplicate it, sell it again, and get the parts, Nelson added. Having something that's custom where you have to wait for 12 weeks to get a billet block or pair of heads, it kills the whole thing. The guys have money, but don't have any time or patience. They don't want to hurt an engine and be out for four months.

Visner who has performed cylinder head and manifold development work for nearly every big name you can think of incorporated all of the wish-list items into the configuration of this engine design to ensure it will withstand well over 4,000 horsepower with ease. The block uses a 400-sized main and connecting rod journals to claim the small-block-configuration weight break.

This engine is designed for big power. The mains are splayed and cross-bolted, with a girdle setup that ties it all together. We wanted to develop a package that's complete from the oil pan to the crankshaft, block, heads, and cam cores, Visner said. Every component is in stock for this combination. Pistons, rods, valves, all that stuff is easy to get, but it does no good for me to have blocks and heads if someone has to wait 16 weeks to get a crankshaft or cam core. We saw that as being an issue, so we stock those. All their cam company has to do is grind the journals to our specifications and then grind the lobes on.

We felt like the way the small-block rules are written is vague, he added. It's either considered a small-block or a spread-bore, non-stock bore space under 500 cubic inches, which leaves it very open.

There remains a debate as to whether splayed main caps or cross-bolted main caps offer more strength; some block designs use one, some the other. Visner explains that Hemi engines are all quite successful with a cross-bolted design. However, with a cross-bolted main, there can also be issues with oil windage. His solution was to combine the two configurations in his design.

We came up with a girdled main assembly. It has a splayed main with a deep, half-inch register and a billet girdle. The end of the cap has a keyway in it, and the girdle locks in from the sided with a cross-bolt on the girdle. There is strength from the sides. The issue with girdled setups has always been that you can't service the mains, but the way that we slotted it, you can service the mains and rods with our billet oil pan. The pan is a one-piece pan with an O-ring that just drops off the girdle and makes it easy to drop the pan and check the bearings, explains Visner.

It has a .400-inch raised big-block Chevy front design that makes sourcing timing components simple. The big-block snout on a small-block crank gives them lots of options.

The design of the cylinder head took him back to his roots in the world of induction system development. He was able to configure the valvetrain to have straight angles that allow for optimal dynamic characteristics, which Visner says capitalizes on the small-block's high-rpm breathing ability. It's also especially important when 60-plus psi of boost pressure is applied to the engine. Intake valves measure 2.380-inch, with a 1.680-inch exhaust valve stuffed in the port. Currently, they offer two different port configurations that easily flow well over 525 cfm at max performance.

All of this stuff is capable of 600 inches, but the rule format for a boosted deal in RvW is a 500-inch cap, Nelson said. Anything bigger than that has to add weight. Woody's engine combination is 493 cubic inches to leave us some room to freshen it up.

He explains that Nelson Competition will be offering a semi-custom, turnkey engine package based around these components from Visner, which could be put together in a week or so as all of the hard parts and most ancillary components are stocking items at one of the two companies.

Darren Breaud built Woody's new Pro Mod-style 69 Camaro at B&B Race Cars, and with this engine configuration, the car can run at 2,500 pounds with unlimited boost. That's quite the setup, and the car can go back and forth between RvW and Pro Mod competition.

I'm of the opinion that the engine needs to be durable, needs to spool a big set of turbos, and the valvetrain needs to let the thing turn 9,500 rpm and be stable, says Nelson.

It's clear that Visner Engine Development had just that type of performance in mind during the engineering process for this engine platform, and it's only a matter of time until Woodruff's car with himself or Craig Sullivan behind the wheel is a significant player in RvW and NMCA VP Racing Lubricants Xtreme Pro Mod.

Sources:

Visner Engine Development

(616) 726-6600

Visnerengine.com

Nelson Competition, Inc.

(727) 321-5756

Facebook.com/nelsoncompetitioninc

Posted By: nmrasalesdept

Oct 28,

2020