By Pat Bateman

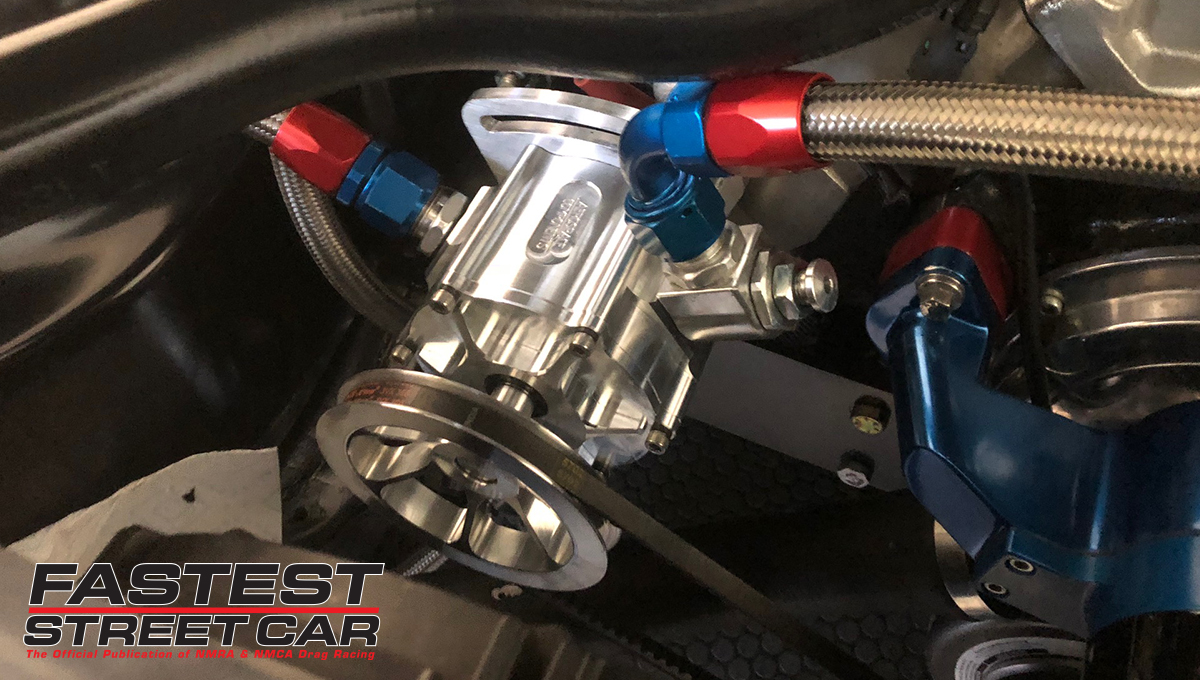

Bolting a vacuum pump to a race engine is an age-old way to improve ring seal, reduce windage, and reduce parasitic losses. In the quest to squeeze every last drop of performance out of a combination, racers are always seeking a bit more. That's why Aerospace Components offers an upgrade to improve its vacuum pumps and extend their lives in the harshest of environments.

Our pumps pull more vacuum and more CFM than other pumps on the market, Kim said. This equals more horsepower, Kim Kussy, president of Aerospace Components Inc., said. Our pumps can be used on small- or large-cubic-inch motors.

To improve upon those pumps, which are available for a variety of big-three big- and small-block engines, the company recently released a hybrid-ceramic bearing upgrade for them. They are said to weigh half as much as traditional bearings and offer up on a tenth of the friction of their steel counterparts. Moreover, they are said to last as much as five times longer and even run cooler.

Stock bearings and the vacuum pumps are made out of steel and engines that run alcohol generate a lot of moisture. This moisture then goes into the pump and rusts out the bearings, Kim explained. Our hybrid-ceramic bearings are a solution to fix that. Aerospace's bearing races are made out of hardened stainless steel with ceramic ball bearings, so they don't rust, last much longer, and are low drag.

That reduced drag is music to a racer's ears. Though the gains from the bearing upgrade are modest, every horsepower counts in some limited classes.

These ceramic bearings have less drag and produce approximately 2 to 4 more horsepower, Kim said. The Aerospace vacuum pump hybrid-ceramic bearings are specifically designed for drag racing application and manufactured in America.

A racer to take advantage of the upgrade was Donnie Edmonds, who runs Big Bertha, a 1969 Chevelle SS 396, in NMCA MagnaFuel Open Comp. He was an early adopter of the new bearings because he wanted to maximize his combo.

I chose to install the ceramic bearings because of the extended life they provide and the loss of resistance in the rotating assembly, Donnie explained. Ceramic bearings advantages are well known in the Stock/Super Stock categories and I wanted to take advantage of anything and everything I could to make my full-bodied, all-steel, 3,700-pound 69 Chevelle run as quick and fast as possible naturally aspirated, of course. To date it has been 9.36 at 142 mph in the quarter and 5.93 at 115 mph in the eighth.

He already ran the Aerospace Components vacuum pump setup on his Chevelle, so Donnie needed only upgrade to the better bearing. The process was pretty straightforward.

The install was very simple, Donnie said. I just removed the pump, packaged it up, and sent it down to Aerospace Components. They had the pump for a few days and it was back within a week and then I just bolted it back on the engine and hooked everything up.

With the new hybrid-ceramic bearings spinning freely in the vacuum pump, Donnie returned to the drag strip and immediately realized improvement.

The car ran its second quickest e.t. ever and the weather conditions were horrible very hot, high DA, and water grains, Donnie said. I hurt the engine right after the Norwalk race last year, so I haven't been able to see the full advantages of the upgrades as of yet

If you want to take full advantage of the upgrade, you can add the hybrid-ceramic-bearing upgrade to a new pump from Aerospace Components for $199. Owners of existing pumps who want to upgrade can return their pumps and have the new bearings installed for $298.

Source

Aerospace Components

727| 347 | 9915