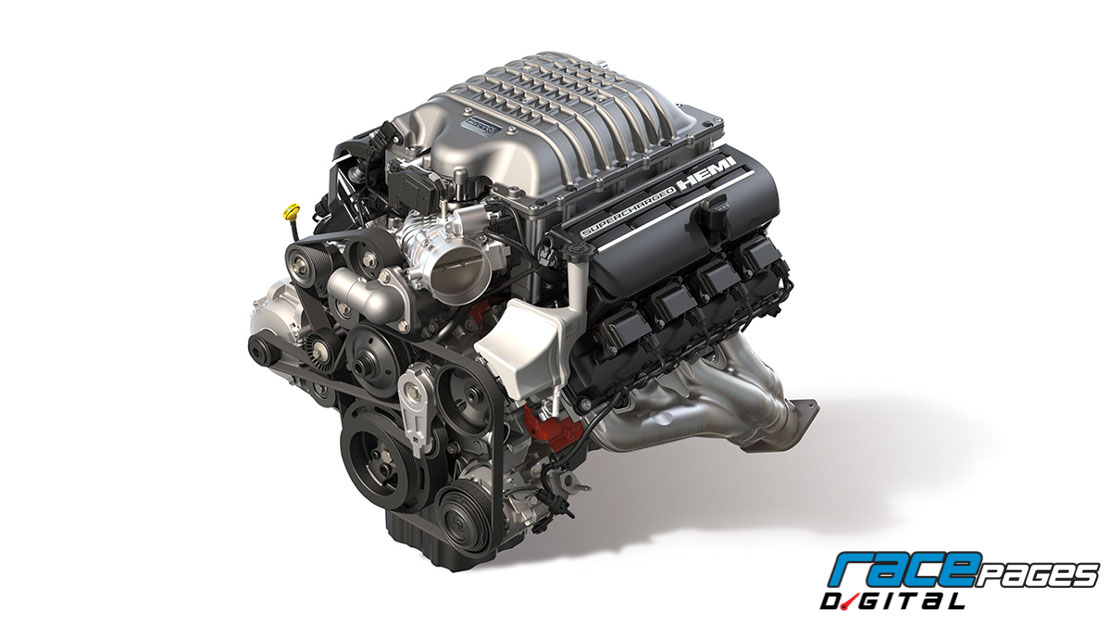

Mopar is unleashing the most powerful production muscle-car engine ever available to builders and enthusiasts with the launch of its newest crate engine the 807-horsepower Hellcrate Redeye 6.2-liter Supercharged HEMI V-8 engine.

With the addition of this new supercharged HEMI, Mopar now offers five HEMI crate engines with a range of 375 to 1,000 horsepower, said Mark Bosanac, Head of Mopar Service, Parts and Customer Care for FCA North America. All Mopar crate engines are quality-tested and factory-backed to deliver proven performance to our enthusiasts.

Rated at 807 horsepower and 717 lb.-ft. of torque on 91-octane pump gas, the new Hellcrate Redeye crate engine is engineered with proven, factory-backed hardware first seen in the wheelie-pulling, record-setting, limited-edition 2018 Dodge Challenger SRT Demon the world's quickest and most powerful muscle car ever. This same supercharged HEMI engine powers the industry's most powerful muscle cars, including the new Dodge Charger SRT Hellcat Redeye, Challenger SRT Hellcat Redeye and the high-horsepower halo of the lineup in 2021, the new 807-horsepower Challenger SRT Super Stock.

2021 marks the year that Dodge is distilled to a pure performance brand with 700+ horsepower models available across the entire Dodge lineup, said Tim Kuniskis, Global Head of Alfa Romeo and Head of Passenger Cars Dodge, SRT, Chrysler and FIAT, FCA North America. The new 807-horsepower Hellcrate Redeye crate engine gives any pre-1976 vehicle owner another opportunity to become a member of the Dodge Brotherhood of Muscle by tapping into the Dodge//SRT power that wasn't available then, but is now.

If you know, you know. If you don't, the new Hellcrate Redeye power plant features significant upgrades versus the standard Hellcrate engine, including:

- Larger supercharger 2.7 liters versus 2.4 liters

- Increased boost pressure: 14.5 psi versus 11.6 psi

- Higher rpm limit: 6,500 rpm versus 6,200 rpm

- Forged alloy steel crankshaft with 90.9-millimeter stroke and revised balancing

- Induction-hardened crank bearing surfaces; individual journal optimized main bearing clearances

- 5150 alloy gun-drilled camshaft optimized for high rpm performance and decreased weight

- Forged high-strength alloy pistons; 30-micron increased piston-to-bore clearance

- Powder-forged connecting rods; upgraded shank and big end; revised ultra-high tensile fasteners

- 100 percent increase in piston-cooling jet flow

- Revised valve-spring design with 33 percent increase in oiling for valve springs and rocker tips for improved lubrication and cooling

- Single-groove collets on valve stems for improved stability

- Oil pan and windage tray optimized for high acceleration tested up to 1.8 g

- Each engine is dyno-tested for 42 minutes before being shipped