Written By Steve Baur

Photography by the Author

Whether it’s in your garage, on the street, or at the track, problems with your modified street or race car can arise at any time and for numerous reasons. When we install a new part and there is an issue, it’s important to consider that it may not be the new part that is the problem. Case in point is a recent fuel system issue that Weldon High Performance’s Jim Craig resolved for NMCA racer Daryl Nelson while on site at the Arrington Performance NMRA/NMCA Power Festival presented by TorqStorm Superchargers.

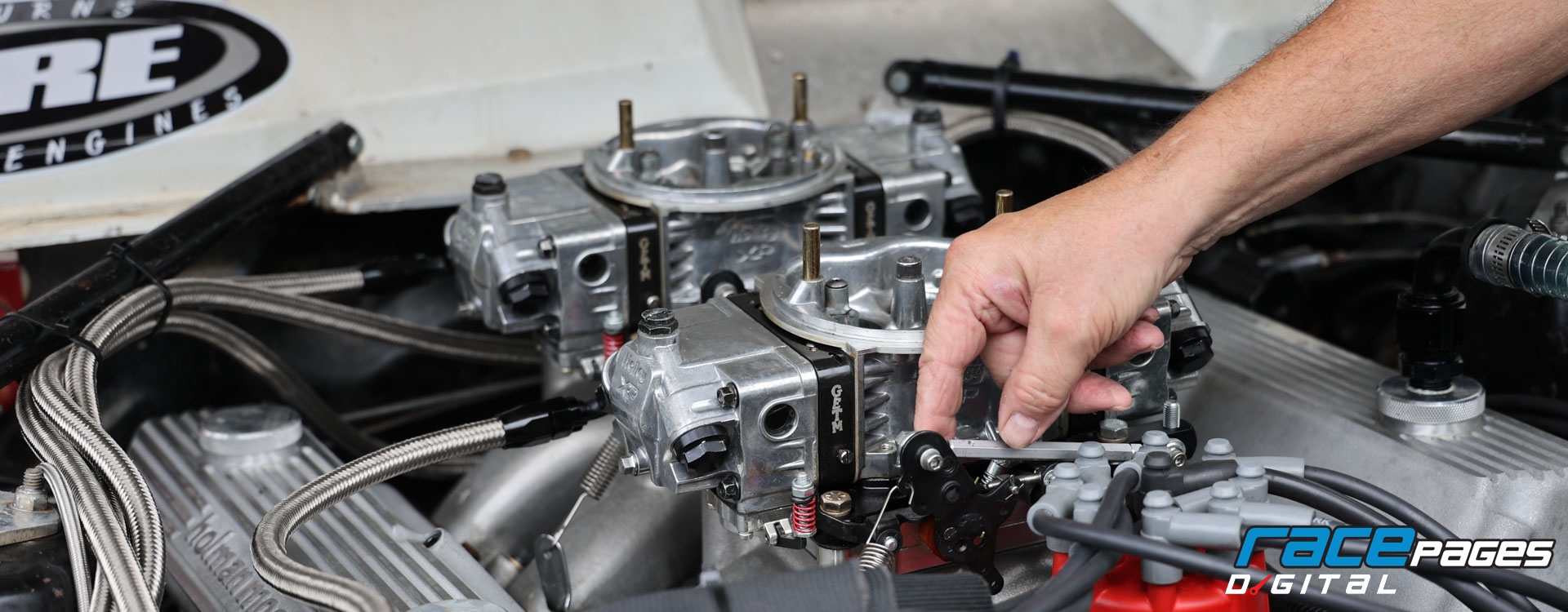

Nelson recently switched his 1966 Ford Fairlane’s powerplant from a 428 Cobra Jet to a 427 mid riser engine with dual Holley HP four-barrel carburetors. To supply the much more capable engine with an adequate amount of fuel, Nelson ordered and installed a new Weldon 16250-A electric fuel pump. While attempting to tune the combination at the track, Nelson noticed that the engine kept flooding out, even though his gauge displayed just 10 psi of fuel pressure. Thankfully, he was able to talk to Craig, who was set up on the manufacturer’s midway at US 131 Motorsports Park.

Craig walked to Nelson’s pit and looked over the fuel system for clues. The first thing that stood out was that the regulator screw was turned nearly all the way in.

“The pump is capable of 50 psi of pressure, but it wasn’t showing that on the gauge,” Craig told us. “The screw being turned in that far should tell you something isn’t right.” Nelson was aiming for 15 psi of fuel pressure, but was seeing a good bit less on the gauge, so it made sense for him to adjust for more pressure.

Nelson was using a 0-15 psi gauge at the dead-head regulator in the engine bay and a 0-50 Psi gauge at the pump. Craig suggested swapping the gauges, and while Nelson did that, Craig backed the regulator screw out all the way, reducing the fuel pressure. Once the gauge swap was made, Craig and Nelson noticed that the pressure was reading accurately and reacting to adjustment.

Luckily for Nelson, he was able to procure a new pair of fuel pressure gauges at the track, as Craig informed him that fellow NMRA/NMCA midway vendor Florida Performance carries all sorts of performance parts and had just what Nelson needed. With the issue sorted out, Nelson was able to fine-tune his engine and improve the performance of his Fairlane as the event went on.

On a similar note, Craig mentioned he was at another race recently and someone approached him about a faulty fuel pump. After conversing with the racer, he told him it was likely the fuel filter causing the issue and asked him if he had checked it. The racer eventually turned with a rather dirty filter element in hand.

Whether it’s a new fuel pump not producing the right results, a new phone not pairing with a set of ear buds, a or some other similar situation, it’s always important to check the simple things first, and to not rule out peripheral items that could be the problem. Sometimes, we can't see the forest for the trees, and it helps to get a second opinion or set of eyes on the problem. Lastly, when it comes to performance parts, no one knows them better than the manufacturers, and their customer support can often get you on the path forward.

Source

Weldon High Performance

(440) 232-2282

www.weldonracing.com

Photography by the Author

Whether it’s in your garage, on the street, or at the track, problems with your modified street or race car can arise at any time and for numerous reasons. When we install a new part and there is an issue, it’s important to consider that it may not be the new part that is the problem. Case in point is a recent fuel system issue that Weldon High Performance’s Jim Craig resolved for NMCA racer Daryl Nelson while on site at the Arrington Performance NMRA/NMCA Power Festival presented by TorqStorm Superchargers.

Nelson recently switched his 1966 Ford Fairlane’s powerplant from a 428 Cobra Jet to a 427 mid riser engine with dual Holley HP four-barrel carburetors. To supply the much more capable engine with an adequate amount of fuel, Nelson ordered and installed a new Weldon 16250-A electric fuel pump. While attempting to tune the combination at the track, Nelson noticed that the engine kept flooding out, even though his gauge displayed just 10 psi of fuel pressure. Thankfully, he was able to talk to Craig, who was set up on the manufacturer’s midway at US 131 Motorsports Park.

Craig walked to Nelson’s pit and looked over the fuel system for clues. The first thing that stood out was that the regulator screw was turned nearly all the way in.

“The pump is capable of 50 psi of pressure, but it wasn’t showing that on the gauge,” Craig told us. “The screw being turned in that far should tell you something isn’t right.” Nelson was aiming for 15 psi of fuel pressure, but was seeing a good bit less on the gauge, so it made sense for him to adjust for more pressure.

Nelson was using a 0-15 psi gauge at the dead-head regulator in the engine bay and a 0-50 Psi gauge at the pump. Craig suggested swapping the gauges, and while Nelson did that, Craig backed the regulator screw out all the way, reducing the fuel pressure. Once the gauge swap was made, Craig and Nelson noticed that the pressure was reading accurately and reacting to adjustment.

Luckily for Nelson, he was able to procure a new pair of fuel pressure gauges at the track, as Craig informed him that fellow NMRA/NMCA midway vendor Florida Performance carries all sorts of performance parts and had just what Nelson needed. With the issue sorted out, Nelson was able to fine-tune his engine and improve the performance of his Fairlane as the event went on.

On a similar note, Craig mentioned he was at another race recently and someone approached him about a faulty fuel pump. After conversing with the racer, he told him it was likely the fuel filter causing the issue and asked him if he had checked it. The racer eventually turned with a rather dirty filter element in hand.

Whether it’s a new fuel pump not producing the right results, a new phone not pairing with a set of ear buds, a or some other similar situation, it’s always important to check the simple things first, and to not rule out peripheral items that could be the problem. Sometimes, we can't see the forest for the trees, and it helps to get a second opinion or set of eyes on the problem. Lastly, when it comes to performance parts, no one knows them better than the manufacturers, and their customer support can often get you on the path forward.

Source

Weldon High Performance

(440) 232-2282

www.weldonracing.com